Description

PVDF tubing is a stronger, more abrasion resistant material than its per-fluorinated (all Carbon-Fluorine – CF2) counterparts such as PTFE, FEP and PFA at moderate temperatures. This is due to its resemblance to the structure of polyethylene (Carbon-Hydrogen – CH2). The alternating CF2 and CH2 pendant groups in the molecular structure imparts a unique blend of mechanical wear, thermal, age-weathering, UV and gamma radiation resistance and high purity properties that is useful in a broad class of applications. The mechanical toughness of PVDF is attributable to its excellent creep, fatigue and cut through resistances.

PVDF offers excellent cost/performance benefits with high purity properties, inertness to attack to a wide range of chemicals, and a use temperature range of -58F to 302F (-50C to 150C). The list of properties offered by PVDF make it a preferred material for applications that require high chemical resistance, flame resistance, good electrical insulation and abrasion resistance. Aerospace, fiber optic (for furcation tubing), and semiconductor applications utilize the flame resistance and good insulation properties of PVDF.

Attributes

- Outstanding resistance to sunlight/UV exposure

- Tremendous chemical resistance to a wide range of aggressive chemicals

- Radiation resistance

- Excellent burn characteristics / flame and smoke properties

- UL 94 Flame Rating V-0

- Easy processing on industry-standard equipment and easy post-processing such as welding and fabrication

- Extremely high purity for the most demanding applications

- Extremely high electrochemical stability

- Excellent abrasion resistance

- High temperature rating: RTI 150º C

- Certifications: USP Class VI, CFR 21 Sec. 177.2600, NSF

Additional Information

IF YOUR ORDER VALUE EXCEEDS $3000, PLEASE CONTACT FLUOROSTORE FOR DISCOUNTED PRICING.

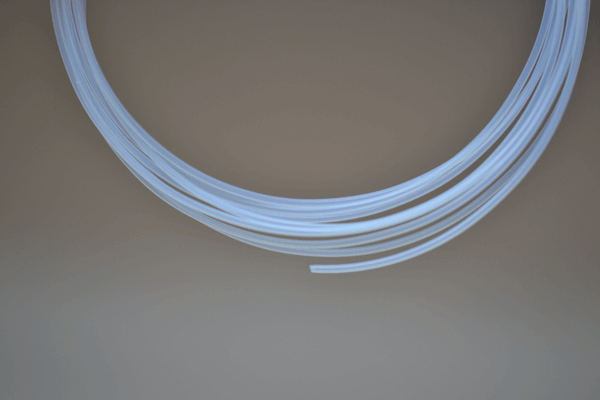

PVDF Standard Tubing

Description

PVDF tubing is a stronger, more abrasion resistant material than its per-fluorinated (all Carbon-Fluorine – CF2) counterparts such as PTFE, FEP and PFA at moderate temperatures. This is due to its resemblance to the structure of polyethylene (Carbon-Hydrogen – CH2). The alternating CF2 and CH2 pendant groups in the molecular structure imparts a unique blend of mechanical wear, thermal, age-weathering, UV and gamma radiation resistance and high purity properties that is useful in a broad class of applications. The mechanical toughness of PVDF is attributable to its excellent creep, fatigue and cut through resistances.

PVDF offers excellent cost/performance benefits with high purity properties, inertness to attack to a wide range of chemicals, and a use temperature range of -58F to 302F (-50C to 150C). The list of properties offered by PVDF make it a preferred material for applications that require high chemical resistance, flame resistance, good electrical insulation and abrasion resistance. Aerospace, fiber optic (for furcation tubing), and semiconductor applications utilize the flame resistance and good insulation properties of PVDF.

Attributes

- Outstanding resistance to sunlight/UV exposure

- Tremendous chemical resistance to a wide range of aggressive chemicals

- Radiation resistance

- Excellent burn characteristics / flame and smoke properties

- UL 94 Flame Rating V-0

- Easy processing on industry-standard equipment and easy post-processing such as welding and fabrication

- Extremely high purity for the most demanding applications

- Extremely high electrochemical stability

- Excellent abrasion resistance

- High temperature rating: RTI 150º C

- Certifications: USP Class VI, CFR 21 Sec. 177.2600, NSF

Additional Information

IF YOUR ORDER VALUE EXCEEDS $3000, PLEASE CONTACT FLUOROSTORE FOR DISCOUNTED PRICING.