Popular Products

Performance Products

PTFE Standard Tubing - All Sizes

Description This is the original fluoropolymer. Great in a wide range of applications from electrical wire insulators, fluid flow tubing, medical d...

View full details

FEP Standard Tubing - All Sizes

Description The properties of FEP tubing drives its use in many applications that require high electrical breakdown voltage, low dielectric const...

View full details

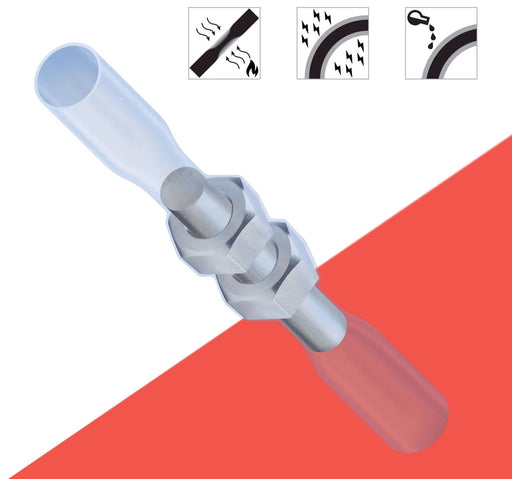

FEP 1.3X Fractional and AWG Heat Shrink Tubing

Description FEP 1.3:1 heat-shrink tubing is a great choice for insulation, encapsulation, and wire harness of components like medical instruments, ...

View full details

PVDF Standard Tubing

Description PVDF tubing is a stronger, more abrasion resistant material than its per-fluorinated (all Carbon-Fluorine – CF2) counterparts such as P...

View full details

FEP Sheets (12" x 12")

Description FEP is used for its high temperature (ability to handle live steam up to 30 psig) low friction properties, and wide-ranging chemical re...

View full details

PFA Sheets (12" x 12")

Description PFA is a modified version of PTFE, except it is optically clear and has a higher tensile strength. Similar to PTFE and FEP, PFA exhibit...

View full details

PVDF Standard Tubing

Description PVDF tubing is a stronger, more abrasion resistant material than its per-fluorinated (all Carbon-Fluorine – CF2) counterparts such as P...

View full details

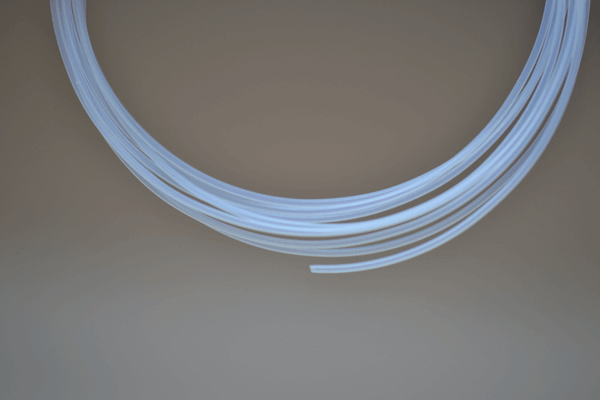

FEP Retractable Coil

Description Organize your work area with self-retracting FEP coils that extend when you need them and retract when you don't. They are compatible w...

View full detailsStore News

Temperature Control and Efficiency in Chemical Processing

In the chemical processing industry, temperature control is vital for the safe and efficient production of high-quality products. From heat exchange systems to jacketed reactors, control valves, and energy recovery systems, the tools available for managing temperature are varied and versatile. By optimizing these systems and integrating advanced technology, chemical plants can improve both their operational efficiency and environmental sustainability.

Maintaining the right temperature for every step of the process not only ensures better product quality but also helps reduce energy consumption, making it a win-win for both the environment and the bottom line. Whether through traditional methods or the latest technological advancements, achieving efficient temperature control in chemical processing will remain a cornerstone of the industry’s success.

The Overlooked Benefits of ETFE Tubing

While PTFE and PFA may continue to be the most recognized fluoropolymers, ETFE tubing presents a compelling case for industries seeking a cost-effective, durable, and chemically resistant solution. Its mechanical strength, UV resistance, and affordability make it a strong contender for a variety of applications. As awareness grows, ETFE could become the go-to material for applications where traditional fluoropolymers are either too expensive or over-engineered.

The Vital Role of Fluoropolymers in Medical Devices: A Timely Reminder for Annual Check-Ups

Annual check-ups are a cornerstone of preventive healthcare, and behind every test, diagnosis, and treatment, fluoropolymers quietly play a crucial role. The next time you visit your doctor for a routine exam, remember the advanced materials working behind the scenes to ensure a safer and more efficient healthcare experience.