FEP 1.3X Fractional and AWG Heat Shrink Tubing

$14.52

Description

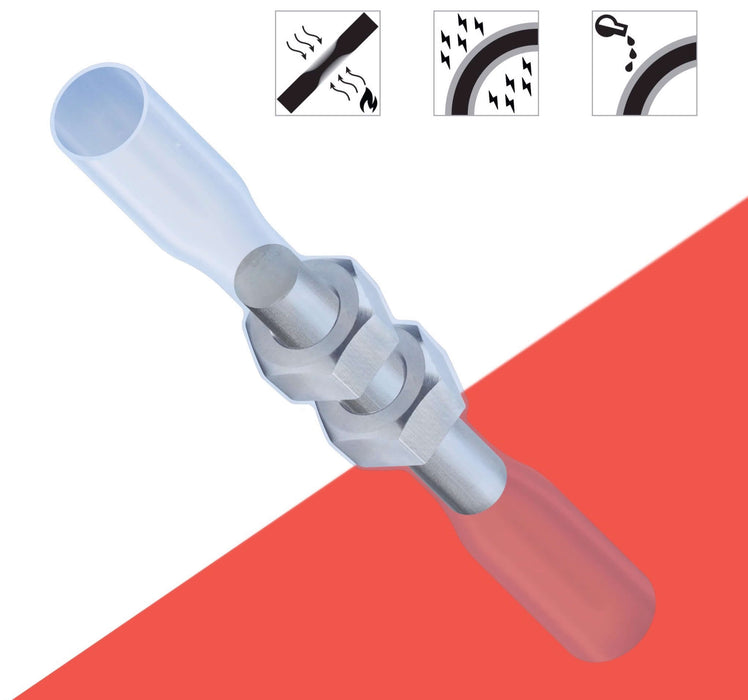

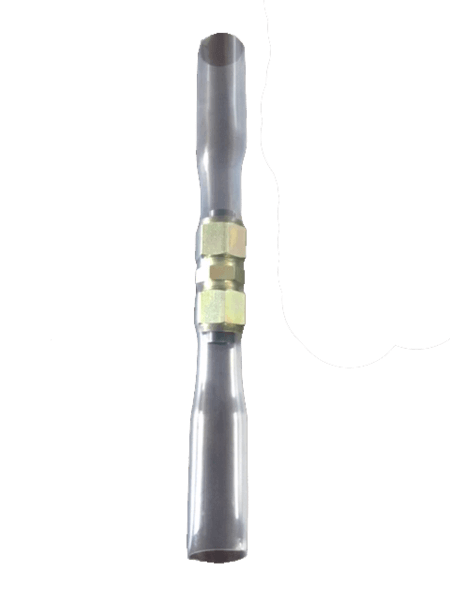

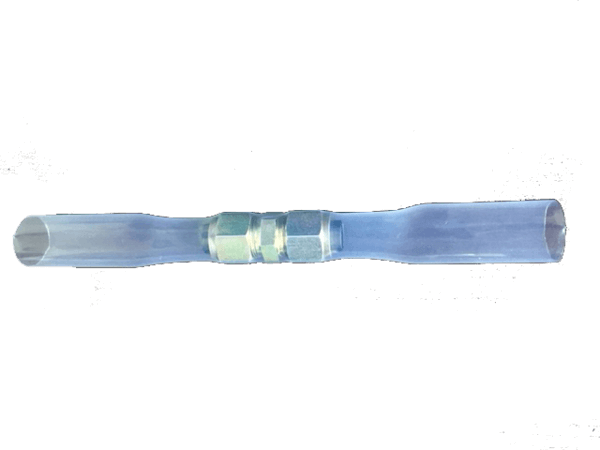

FEP 1.3:1 heat-shrink tubing is a great choice for insulation, encapsulation, and wire harness of components like medical instruments, temperature probes, roll covers, lighting, hoses, wires and cables, and more.

Attributes

- Resistance to high temperatures (450 F / 232 C)

- Excellent dielectric strength to aid in electrical insulation

- Flame resistant - UL 94 V-0 rated

- Conforms to AMS-DTL-23053/11 (Mil 23053/11)

- Sterilization - tolerates Gamma, ETO, e-beam, and autoclave protocols

- Transparent in color to monitor components

Sizing

Standard sizes are shown in the chart below. The "Expanded ID" is the supplied ID. "Recovered ID" refers to the final dimension after shrinking.

Nominal Diameter |

Expanded ID |

Recovered ID |

Recovered Wall Thickness |

3/8" |

0.500" |

0.383" |

0.015+/-0.004" |

7/16 |

0.580 |

0.448 |

0.020+/-0.004 |

1/2 |

0.666 |

0.510 |

0.020 +/- .004 |

5/8 |

0.830 |

0.637 |

0.025 +/- .003 |

3/4 |

1.000 |

0.764 |

0.030 +/- .004 |

7/8 |

1.170 |

0.891 |

0.035 +/- .004 |

1 |

1.330 |

1.020 |

0.035 +/- .004 |

1 1/8 |

1.500 |

1.145 |

0.035 +/- .004 |

1 1/4 |

1.666 |

1.270 |

0.035 +/- .004 |

1 3/8 |

1.833 |

1.390 |

0.035 +/- .004 |

1 1/2 |

2.000 |

1.570 |

0.035 +/- .004 |

Heat Shrinking Methods

OVEN

- Parts may be charged into a hot or room temperature oven. The oven temperature must be increased to more than the “shrinking” temperature.

- Parts should be ideally suspended or supported without touching the hot oven surfaces

- Uniform application of heat is essential to prevent wrinkling

- With small parts, a fast cycle (in and out of the oven rapidly) may be used to shrink the tubing, avoiding unnecessary heating

HEAT GUN with Temperature Range 500 F to 700 F (260 C – 400 C)

- A heat gun is a convenient and practical tool to apply heat when an oven is not available or not necessary

- Parts may be covered one at a time

- Uniform shrinkage requires rotating the part while heat is being applied. Baffles may be used to achieve uniform heat distribution around the part

- For larger parts, heat distribution can be improved by assembling baffles of sheet metal, or ceramic plate to direct and distribute the heat uniformly around the part