The Overlooked Benefits of ETFE Tubing

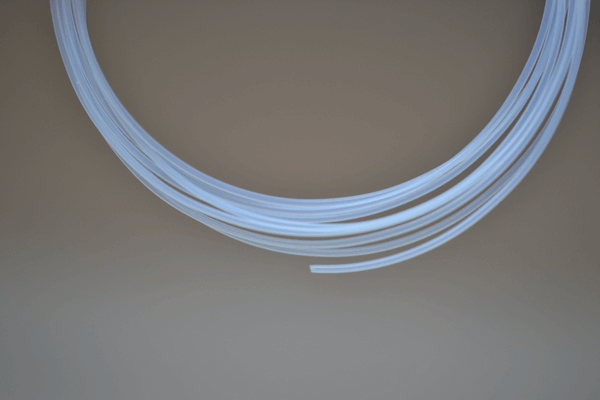

Fluoropolymers have long been the backbone of high-performance tubing solutions across multiple industries. While materials like PTFE and FEP tend to dominate discussions, one material that often goes unnoticed despite its excellent properties is ETFE (Ethylene Tetrafluoroethylene). Standard ETFE tubing offers a unique combination of strength, chemical resistance, and cost-effectiveness, making it an underrated yet powerful choice for various applications.

What is ETFE Tubing?

ETFE is a high-performance fluoropolymer known for its excellent mechanical properties and chemical resistance. Originally developed for the aerospace industry, it has since found applications in medical, industrial, and architectural settings. Compared to other fluoropolymers like PTFE or PFA, ETFE is more rigid, has higher impact resistance, and provides a great balance between performance and affordability.

Why Does ETFE Tubing Go Overlooked?

Despite its impressive capabilities, ETFE tubing is often overshadowed by more well-known fluoropolymers such as PTFE, PFA, and FEP. Some of the reasons include:

-

Brand Dominance: PTFE has been the industry standard for decades, making it the go-to material for high-performance tubing.

-

Lack of Awareness: Many manufacturers and end-users simply aren't familiar with ETFE’s advantages.

-

Limited Applications in High-Heat Environments: ETFE has a lower maximum operating temperature compared to PTFE and PFA, making it less ideal for extreme heat applications.

Key Benefits of ETFE Tubing

Despite its underappreciation, ETFE tubing offers significant benefits across various industries:

1. Exceptional Chemical Resistance

Like other fluoropolymers, ETFE is highly resistant to a broad range of chemicals, including acids, bases, and organic solvents. This makes it ideal for laboratory and industrial fluid handling systems where contamination resistance is crucial.

2. Superior Mechanical Strength

One of the standout features of ETFE is its toughness. Unlike PTFE, which can be prone to creep and deformation under stress, ETFE maintains its structural integrity under high pressure and impact, making it a great choice for demanding mechanical applications.

3. High Transparency and UV Resistance

ETFE is naturally transparent and resistant to UV radiation, making it a great choice for applications that require visibility and exposure to sunlight. This has made it a popular choice for architectural coatings and greenhouse structures, where durability and light transmission are essential.

4. Lower Cost Compared to PTFE and PFA

ETFE offers many of the benefits of higher-end fluoropolymers at a fraction of the cost. For industries that require chemical resistance and durability but don’t need extreme heat tolerance, ETFE is a cost-effective alternative.

5. Lightweight and Flexible

While ETFE is mechanically strong, it remains lightweight and flexible, making it easy to handle and install in various applications. This makes it particularly useful in aerospace, medical, and automotive industries where weight savings are critical.

Applications of ETFE Tubing

ETFE tubing is widely used across multiple industries, including:

-

Medical: Fluid transport and biocompatible tubing.

-

Industrial: Chemical processing, fluid transfer, and pneumatic applications.

-

Aerospace: Wire and cable insulation due to its lightweight and durability.

-

Architecture: Transparent roofing and greenhouse applications due to its UV resistance.