Bowden Tubes for 3D Printing

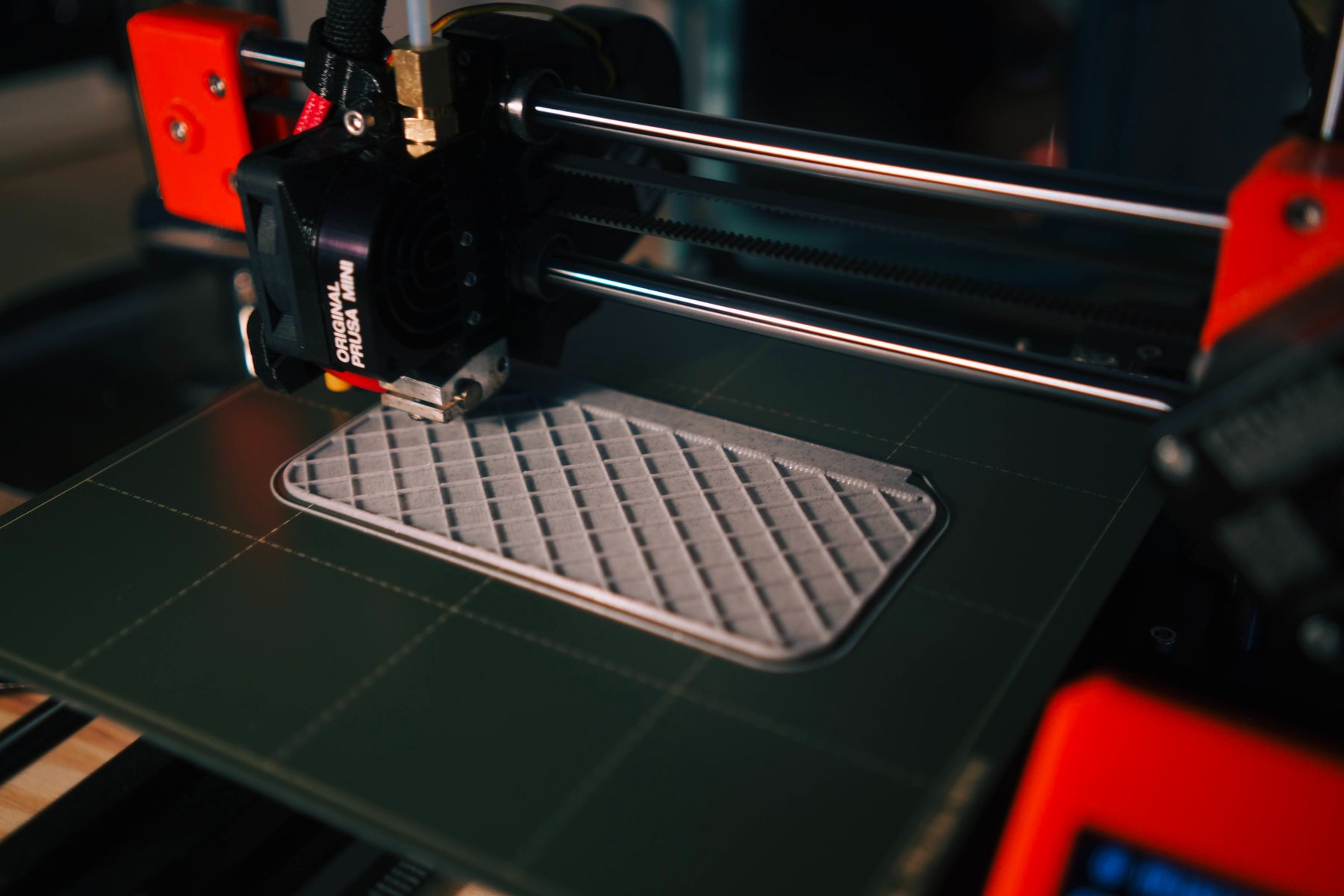

Over the past decade, 3D printing has become a very popular way to create just about anything you can imagine. 3D printers are truly complex pieces of technology that are made up of many parts, one of the most important being the Fluorotherm Bowden tube that delivers the plastic to the print head, but what exactly is a Bowden tube and what does it do?

A Bowden tube is an essential line that helps direct the fibers from the motor to the print head. It is necessary for 3D printers that use Bowden extruders instead of direct drive extruders.

What Exactly Is a Bowden Tube

The Bowden tube is a synthetic tubing that is made of Polytetrafluoroethylene (PTFE), which is key in 3D printing. It is the highway that delivers the raw material used to make a print from the extruder to the print head where the printer creates an object.

The PTFE that Bowden tubes are constructed of is very resistant to high temperatures, hydrophobic, non-stick, flexible, and dense, which is why this material is used. It helps protect the plastic from breaking or losing its form while it travels from the motor to the print head.

Bowden Extruders Vs. Direct Drive Extruders

There are two different types of extruders on 3D printers, Bowden and direct drive. They are designed slightly differently but they both consist of an extruder pushing the medium, which is usually Polylactic Acid (PLA plastic), metal, carbon fiber, or graphite, into a heated tip.

The main difference is that a direct drive extruder propels the medium directly into the print head, whereas Bowden extruders have space in between the motor and the print head, which is why they require the Bowden tube to transport the medium to the heated head.

Other Applications of The Bowden Tube

Bowden tubing (PTFE tubing) has gained significant popularity over the past two decades because it has proven effective as a safe and easy-to-use material in various industrial, chemical, automotive, medical, food, electrical, and consumer-based applications.

Some of these applications include:

- Tubing is used on medical instruments that are used inside medical patients, such as catheters

- Coating for high voltage wires that are exposed to excessive amounts of heat

- It can be treated with chemicals so that it shows up on Xrays

- Serves as a guide for transferring hot fluids in automotive settings

- Used as a replacement for glass in chemical labs because it is more durable

- Its high melting point allows it to insulate metals that experience exposure to high temperatures

- Used to make everything from nonstick cookware, gaskets, and even airplane fittings

Final Thoughts

While Bowden tubes are primarily used for transferring plastic between the motor and print head of 3D printers, they have a multitude of extra uses in which they excel. As a type of PTFE tubing that can handle high temperatures, is hydrophobic, flexible, chemically inert, non-toxic, and resistant to UV light, it isn’t hard to see why it is used in so many different applications.